5th Axis teamed up with TraceParts to develop a 3D configurator and CAD catalog solution to digitize the selection of 5th Axis workholding products.

5th Axis started as a machine shop with one machine in 2004. Eighteen years later, 5th Axis has expanded to over one hundred 3-, 4-, and 5-axis machines manufacturing many different parts every day. After years of research by its world class engineers and machinists, 5th Axis has developed manufacturing processes and patented tooling systems, the result of which is a robust suite of workholding products and solutions.

Industrial manufacturers invest millions of dollars on machine tools to make the parts contained in their products. Manufacturing products at competitive prices requires optimizing throughput by designing machining processes that result in the highest number of quality parts manufactured in the shortest time. Workholding solutions are a strategic part of this optimization process.

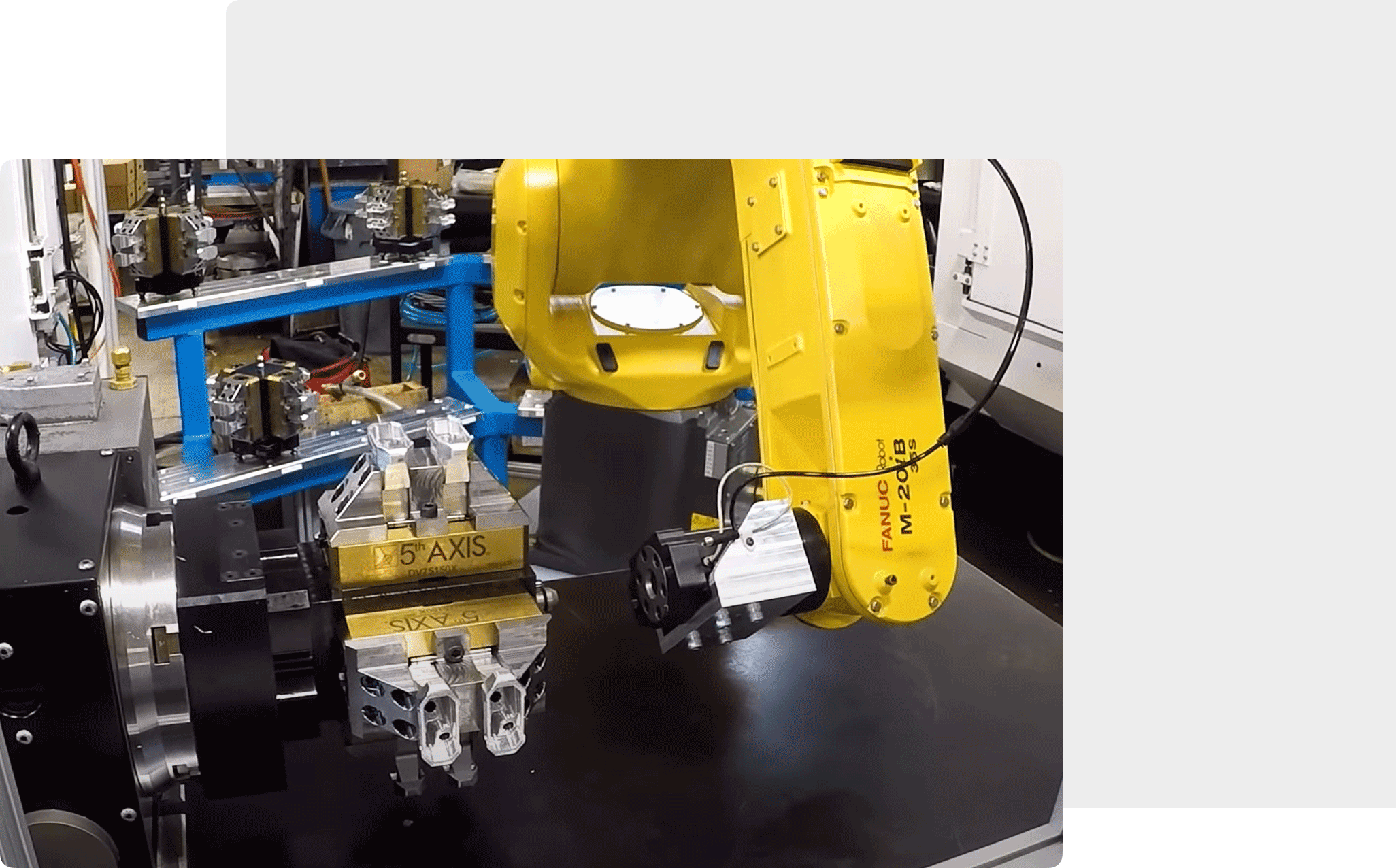

The example below utilizes a 5th Axis “Small Double Station Vise,” which allows two parts to be manufactured in one vise, and in this case it replicated four times on an indexing table to allow eight parts to be manufactured in one setup. The Fanuc robot moves the setup between stations, including to the machine tool to machine the parts.

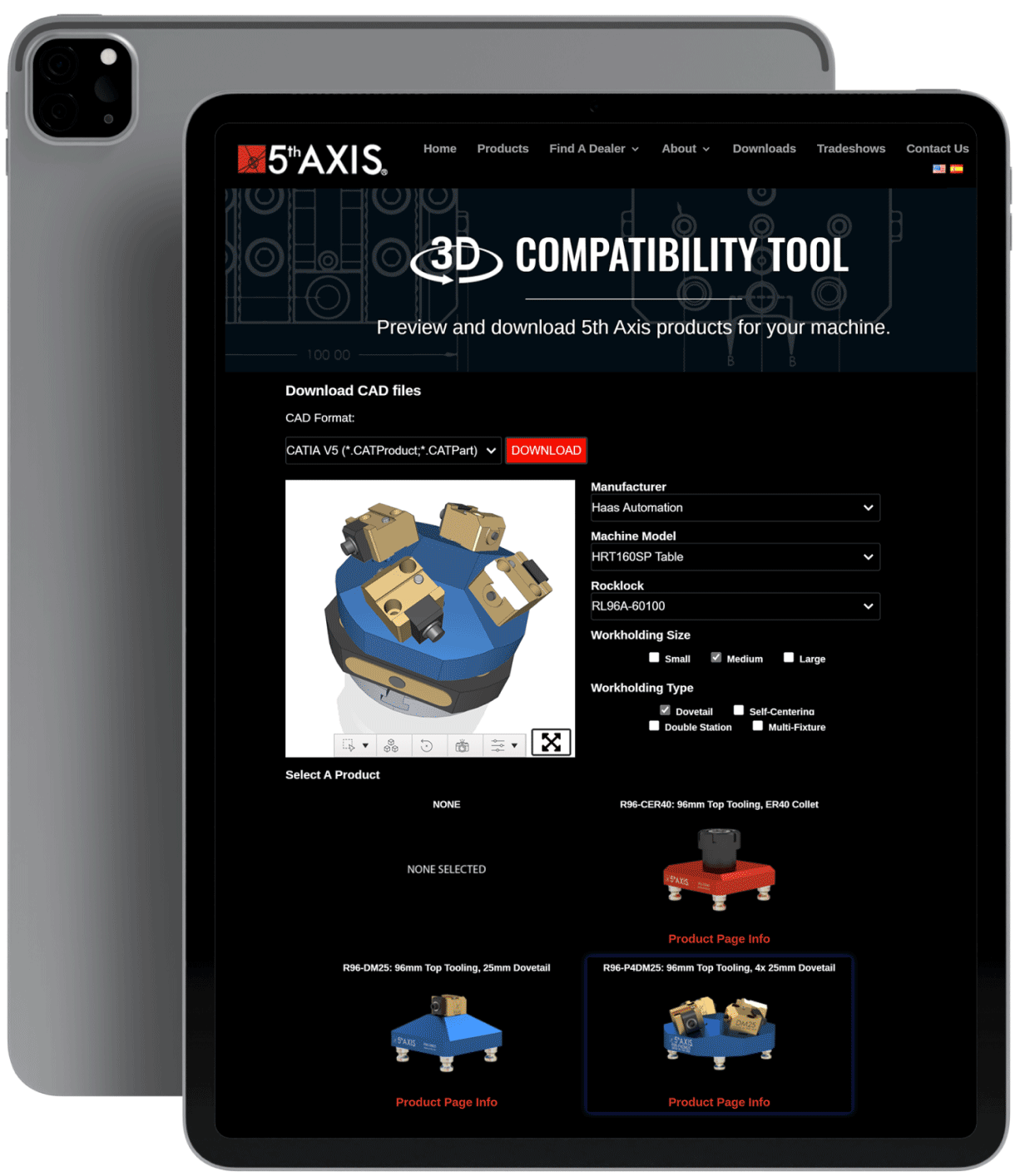

5th Axis teamed up with TraceParts to develop a 3D configurator and CAD catalog solution to digitize the selection of 5th Axis workholding products. The TraceParts CAD-content platform and Helioz Technologies zipCPQ™ products and services now streamline the configuration and purchasing process for 5th Axis customers.

By providing the machine tool manufacturer name and model number, the user is presented with compatible 5th Axis RockLock™ base options, and by selecting the workholding size and type, 5th Axis workholding options are presented.

The 3D assembly model of the configured workholding solution is displayed interactively, and the CAD model is available for download in 70+ native and neutral CAD formats for manufacturing setup validation. 5th Axis workholding products are also available on the TraceParts Publishing Network, accessible by millions of engineers.

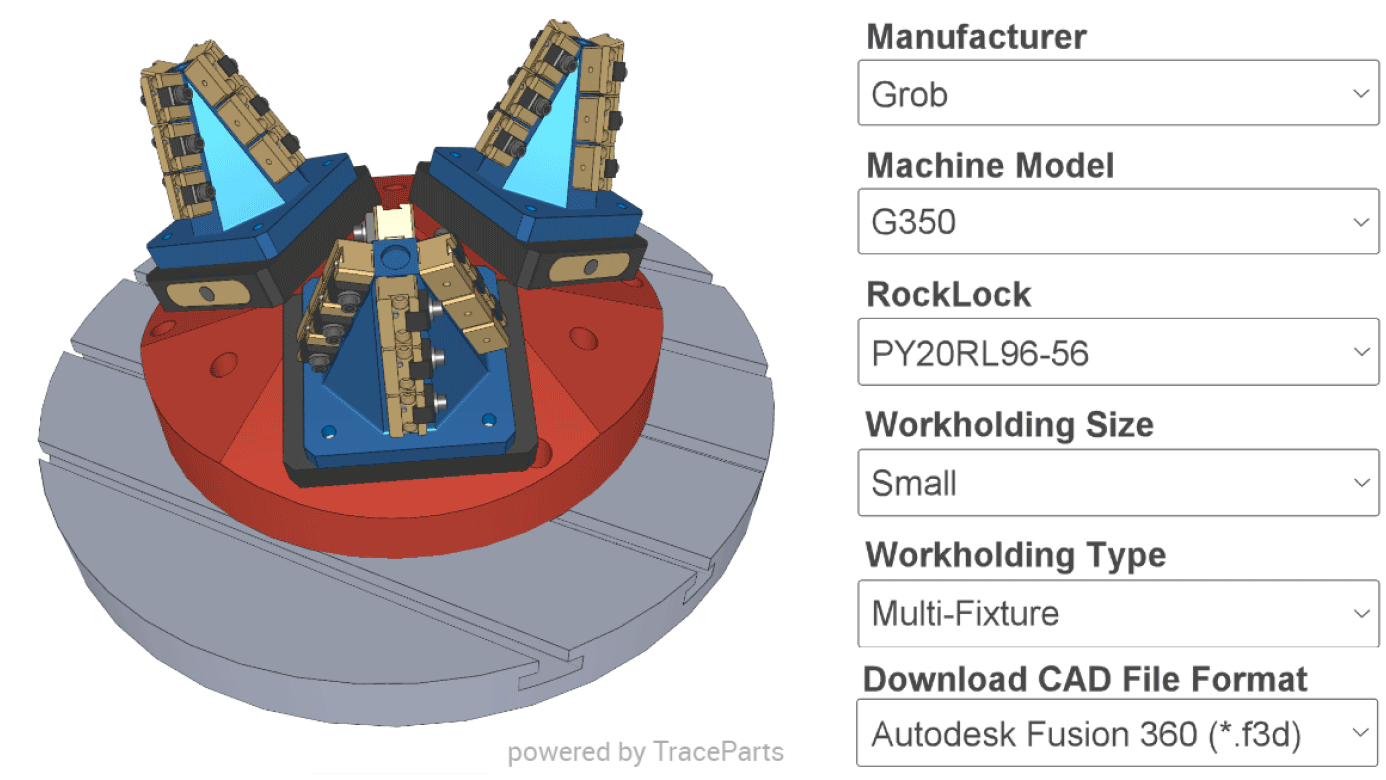

The 5th Axis configured workholding solution shown below allows thirty-six parts to be fixtured in this setup to speed the manufacture of parts. With six clicks, a 5th Axis customer can configure the exact workholding product set to maximize throughput on the machine, and the setup can be validated by downloading it in more than seventy CAD file formats.

5th Axis products are also available on the TraceParts CAD Content Platform at www.traceparts.com, as shown in the example below.

We promote our workholding solutions via a YouTube video which has more than 118,000 views and we’ve emailed hundreds of thousands of prospects to promote the TraceParts / Helioz zipCPQ™ 3D Product Configurator and direct them to that page on our website. This is no longer a cute plugin for our website, it is the heart of our business.

Chris Taylor

Co-Founder of 5th Axis

5th Axis is delighted to be publishing its 3D RockLock™ bases, fixtures, top tooling setups and pull studs & accessories with TraceParts both on its website and the TraceParts Publishing Network. Our customers appreciate the ability to access 5th Axis product information in more than seventy (70) engineering design (CAD) formats to streamline their selection of our products.

Mathew Evans

Vice President, Workholding Products at 5th Axis

© 2022 Helioz Technologies